|

|

- or - Rough and dirty vacuum testing: my path towards high vacuum |

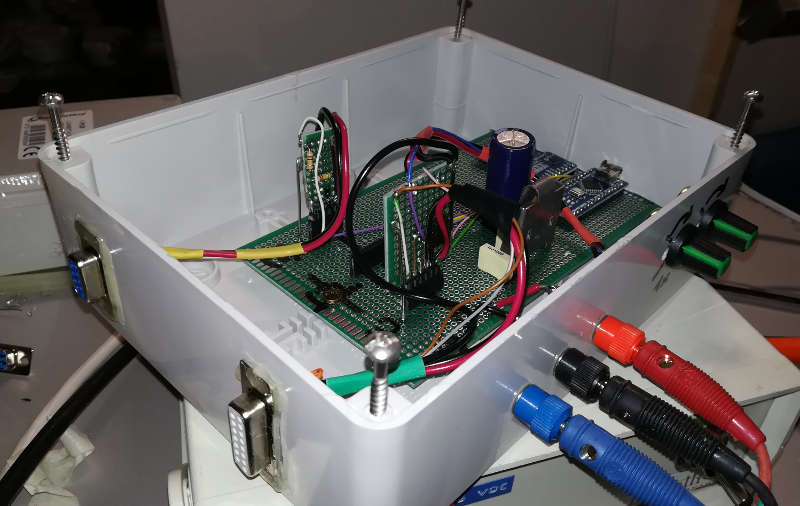

#include <Wire.h>

#include <Adafruit_ADS1015.h>

// ADS1115 addresses: (GND - 0x48) (SDA 0x4A)

Adafruit_ADS1115 ads1(0x48); /* Use this for the 16-bit version */

Adafruit_ADS1115 ads2(0x4A); /* Use this for the 16-bit version */

void setup(void)

{

// Serial monitor

Serial.begin(9600);

Serial.println("Hello!");

ads1.setGain(GAIN_ONE); // 1x gain +/- 4.096V 1 bit = 2mV 0.125mV

ads2.setGain(GAIN_ONE); // 1x gain +/- 4.096V 1 bit = 2mV 0.125mV

ads1.begin();

ads2.begin();

}

void loop(void)

{

// ADC reading

int16_t adc1_0, adc1_1, adc1_2, adc1_3; // FIRST ADC

int16_t adc2_0, adc2_1, adc2_2, adc2_3; // SECOND ADC

// Read from first ADC

adc1_0 = ads1.readADC_SingleEnded(0);

adc1_1 = ads1.readADC_SingleEnded(1);

adc1_2 = ads1.readADC_SingleEnded(2);

adc1_3 = ads1.readADC_SingleEnded(3);

// Read from second ADC

adc2_0 = ads2.readADC_SingleEnded(0);

adc2_1 = ads2.readADC_SingleEnded(1);

adc2_2 = ads2.readADC_SingleEnded(2);

adc2_3 = ads2.readADC_SingleEnded(3);

// Average values in time

double avg_bits_1_0 = 0; // Setpoint Mass flow controller

double avg_bits_1_1 = 0; // Output Mass flow controller

double avg_bits_2_0 = 0; // Output 10 Torr pressure gauge

int Navg = 250;

for(int ii = 0; ii < Navg; ++ii)

{

avg_bits_1_0 += (double)(adc1_0)/Navg;

avg_bits_1_1 += (double)(adc1_1)/Navg;

avg_bits_2_0 += (double)(adc2_0)/Navg;

}

// Convert to voltages

double Vsetpoint_mV = avg_bits_1_0*0.125; // Setpoint voltage Mass flow controller

double Voutput_mV = avg_bits_1_1*0.125; // Output voltage Mass flow controller

double Voutput_mV_Pressure = avg_bits_2_0*0.125; // Output voltage pressure gauge (divided by two)

double P_Torr = Voutput_mV_Pressure/1000/5*10;

Serial.print("\n");

Serial.print("Setpoint - He: "); Serial.print(Vsetpoint_mV); Serial.print(" mV "); Serial.print(Vsetpoint_mV/1000*30/5); Serial.print(" sccm\n"); // "30" -> 30sccm FS mass flow controller

Serial.print("Output - He: "); Serial.print(Voutput_mV); Serial.print(" mV "); Serial.print(Voutput_mV/1000*30/5); Serial.print(" sccm\n"); // "30" -> 30sccm FS mass flow controller

Serial.print("\n");

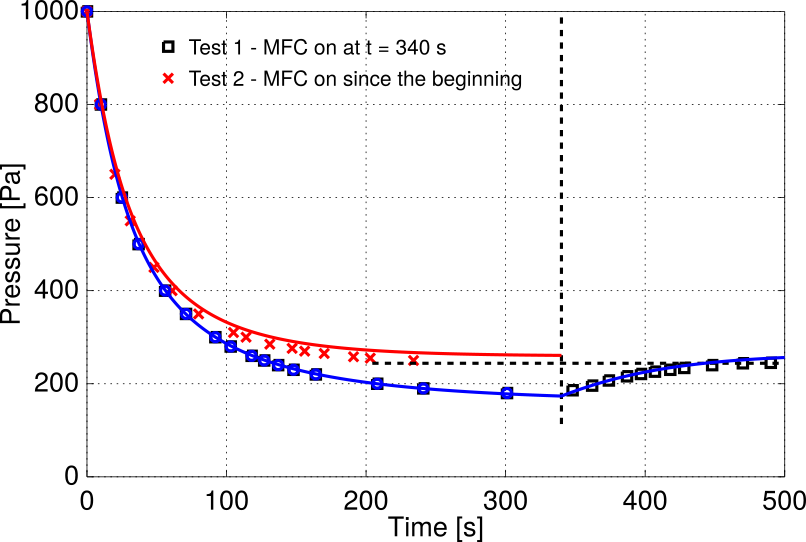

Serial.print("P: "); Serial.print(Voutput_mV_Pressure); Serial.print(" mV "); Serial.print(P_Torr); Serial.print(" Torr = "); Serial.print(P_Torr*133); Serial.print(" Pa\n");

delay(1000);

}